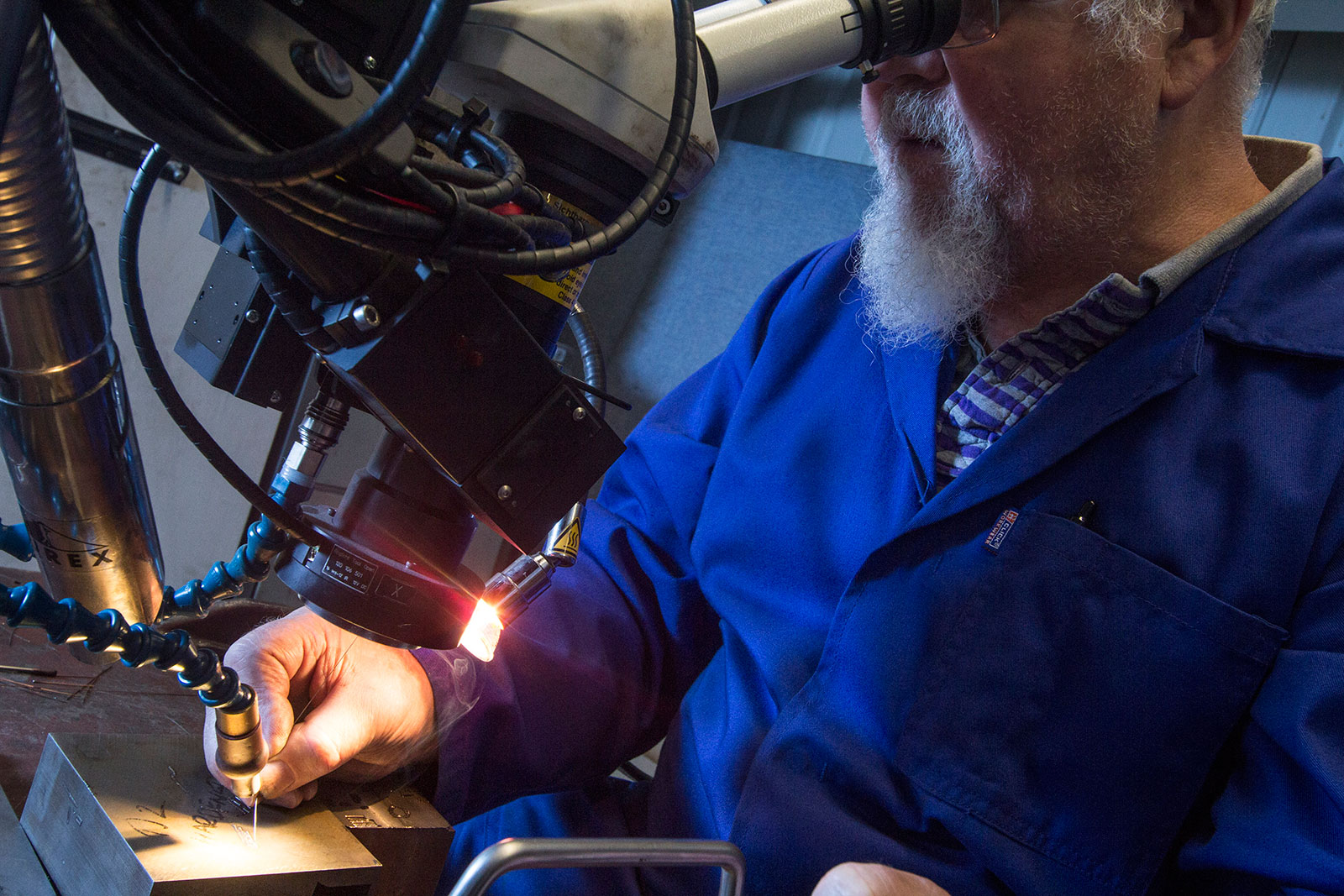

KPT laser welding service

Laser welding allows us to weld together materials that would previously be considered un-weldable, thanks to how little heat laser welding builds up and how precise we’re able to be with the technology.

This allows us to undertake e.g. tool maintenance without having to fully strip the tool down, saving our customers significant time and money. It also opens up our workshop to whole new avenues of precision engineering here in Wales.

The system lets us weld objects as small as 0.2mm (using a microscope) or as large as major mould or press tools, without the risk of distorting the items being welded and without significant rework needed. This is due to the laser’s system of pulsing rather than offering up continuous heat – it heats a fraction of a second at a time so that the target metal melts but the surrounding area doesn’t soak up extra heat (and associated stress on the material). We can use filler wire to weld together materials which previously would not have been candidates for welding, with a pure, clean and neatly-finished weld with the minimum of fuss.