Knight introduces the ROFIN Star Laser Welder – Tool Open II

PRECISION The use of laser technology allows us to target even the most narrow and complicated areas to ensure only the highest quality tool repairs. FLEXIBILITY The Tool Open II is capable of processing a variety of materials with a hardness of up to 64HRC –including aluminium, copper and nickel. HIGH STANDARD FINISH The laser...

Read MoreTrialling Under Way for Major UK Household Brand

Trialling is now under way after the successful development and manufacture of a 17 tool suite for a major UK household electronic goods manufacturer. Working with our expert engineers and vast range of machines,all tools produced hit all targets for T1, modification and pre-production. All complete within a very tight schedule. The Knight Manufacturing Group will...

Read MoreAddition of New HAAS VF-4SS

With the introduction of a new HAAS VF-4SS, our CNC machine list has expanded further. With a 12,000-rpm 40-Taper Spindle, high-speed rapids on all axes and 50″ x 20″ x 25″ range, this high-performance Super-Speed vertical machining center will allow us to provide high-volume production with reduced cycle times. This makes the whole process...

Read MoreReshoring gathers pace

Reshoring – the practice of bringing manufacturing back from the Far East to Europe – is gathering momentum. Consultants PwC, in a recent report, noted that the trend could create between 100,000 and 200,000 extra jobs in the UK over the next decade, boosting national output by up to £12 billion. Reshoring is...

Read MoreKnight supports product designers

With its one-stop portfolio of skills, the Knight Group is increasingly being called on by product designers to support new product development. Prototyping, mould design and short run batch manufacturing can all be carried out within the group, providing a short cut to market testing. And for those whose products really start to see...

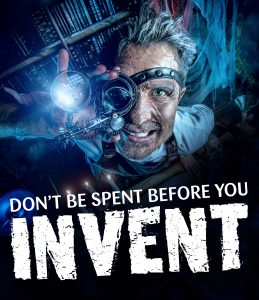

Read MoreSpread the cost of Tooling

Our country is full of innovators, inventors and budding geniuses, bursting with clever ideas to take product design forward and make a name for themselves. But we have to accept that getting an idea from fag-packet scrawling to in-the-hand product is a long and challenging road, and many designers will cite the cost of tooling...

Read More